塑性成形與模具專業英語 | 維持健康的好方法 - 2024年11月

塑性成形與模具專業英語

宋建麗主編的《塑性成形與模具專業英語》共13章,內容主要包括常用工程材料及熱處理基礎,金屬塑性成形基礎,鍛造、軋制工藝及模具,擠壓、拉拔工藝及模具,板料成形工藝及模具,常用模具材料及熱處理,塑料成形工藝及模具,金屬鑄造工藝與模具,模具材料與壽命,金屬和塑料成形設備,模具制造方法及模具CAD/CAM/CAE等。本書較全面地介紹了傳統的塑性成形工藝與模具方面的知識,又兼顧了先進的塑性成形工藝與模具的制造工藝及方法。每節后都附有專業詞匯、詞組及注釋。本書圖文並茂,基本工藝、原理和結構、設備等大多附有圖示說明,以利於學生閱讀和理解課文,記憶和掌握專業詞匯和術語。此外,本書還附有科技英語的特點及翻譯方法與技巧、科技論文摘要寫作介紹等方面的有關內容,可幫助學生提高閱讀和翻譯能力。 《塑性成形與模具專業英語》可作為高等院校材料成形及控制工程專業的本科生教材,也可作為相關專業的研究生教材,或供從事塑性成形及模具加工生產與研究開發工作的工程技術人員參考。

前言CHAPTER 1 FUNDAMENTALS OF MATERIALS 1.1 Metals and Nonmetals 1.2 Ferrous Metals, Nonferrous Metals and Alloys 1.3 Polymers 1.4 Mechanical Properties of MaterialsCHAPTER 2 HEAT TREATMENT OF METALS 2.1 Principle of Heat Treatment of Metals 2.2 Heat Treatment Processes 2.3 Heat Treatment of Die Materials 2.4 Surface Treatment of Die Materials 2.5 Heat-Treating Furnaces and EquipmentCHAPTER 3 FUNDAMENTALS OF METAL PLASTIC FORMING 3.1 Introduction of Metal Forming Processes 3.2 Cold, Warm and Hot Working 3.3 Elastic Deformation and Plastic Deformation 3.4 Stress-Strain Curve 3.5 Tresca and Von Mises Yield CriteriaCHAPTER 4 FORGING AND ROLLING PROCESSES AND DIES 4.1 Introduction of Forging Processes 4.2 Economics of Forging 4.3 Open-Die Forging Operations 4.4 Impression-Die and Closed-Die Forging Operations 4.5 Other Forging Operations 4.6 Rolling Processes 4.7 Forging Defects 4.8 Forging Die DesignCHAPTER 5 EXTRUSION AND DRAWING PROCESSES AND DIES 5.1 Introduction of Extrusion Processes 5.2 Hot Extrusion 5.3 Cold Extrusion 5.4 Extrusion Defects 5.5 Drawing Process and Die DesignCHAPTER 6 SHEET-METAL FORMING PROCESSES AND DIES 6.1 Introduction of Sheet-Metal Forming 6.2 Characteristics and Formability of ShOrt M’’etals 6.3 Shearing Process 6.4 Blanking and Punching 6.5 Bending 6.6 Deep Drawing 6.7 Other Sheet-metal Forming Processes 6.8 Specialized Sheet-metal, Forming ProcessesCHAPTER 7 PLASTICS FORMING PROCESSES AND MOLDS 7.1 Injection Molding 7.2 Extrusion and Sheet Forming of Plastics 7.3 Compression Molding 7.4 Plastic Component and Mould DesignCHAPTER 8 METAL-CASTING PROCESSES AND MOLDS 8.1 Introduction of Casting Processes 8.2 Sand Casting 8.3 Evaporative Pattern Casting 8.4 Investment Casting 8.5 Semi-Solid Metal Casting 8.6 Other Casting MethodsCHAPTER 9 MATERIALS AND FAILURE OF DIES 9.1 Selection of Die Materials 9.2 Principal Forms of Die Failure 9.3 General Conceptions and Criteria of Die Failure 9.4 Factors Influencing the Life and Failure of Dies 9.5 Procedures of Failure AnalysisCHAPTER 10 METALS AND PLASTICS FORMING MACHINES 10.1 Crank Presses 10.2 Screw Presses 10.3 Hydraulic Presses 10.4 Hammers 10.5 Injection Molding MachineCHAPTER 11 DIE MANUFACTURING METHODS 11.1 Fabrication Procedures of Impression Dies 11.2 Conventional Machining of Die Components 11.3 Copy Milling and NC ( Numerical Control) Machining of Die Cavities 11.4 Electrical-Discharge Machining (EDM) 11.5 Electrochemical Machining (ECM) 11.6 Rapid Prototyping Manufacturing (RPM) 11.7 Rapid Tooling (RT) TechnologyCHAPTER 12 CAD/CAM/CAE OF DIES 12.1 CAD 12.2 CAM 12.3 CAE 12.4 Introduction of CAD/CAM/CAE SoftwareCHAPTER 13 CHARACTERISTICS, WRITING AND TRANSLATION TECHNIQUES OF SCIENTIFIC ENGLISH 13.1 專業英語的語法特點 13.2 專業英語的翻譯 13.3 論文標題的漢譯英 13.4 論文摘要的撰寫與翻譯參考文獻

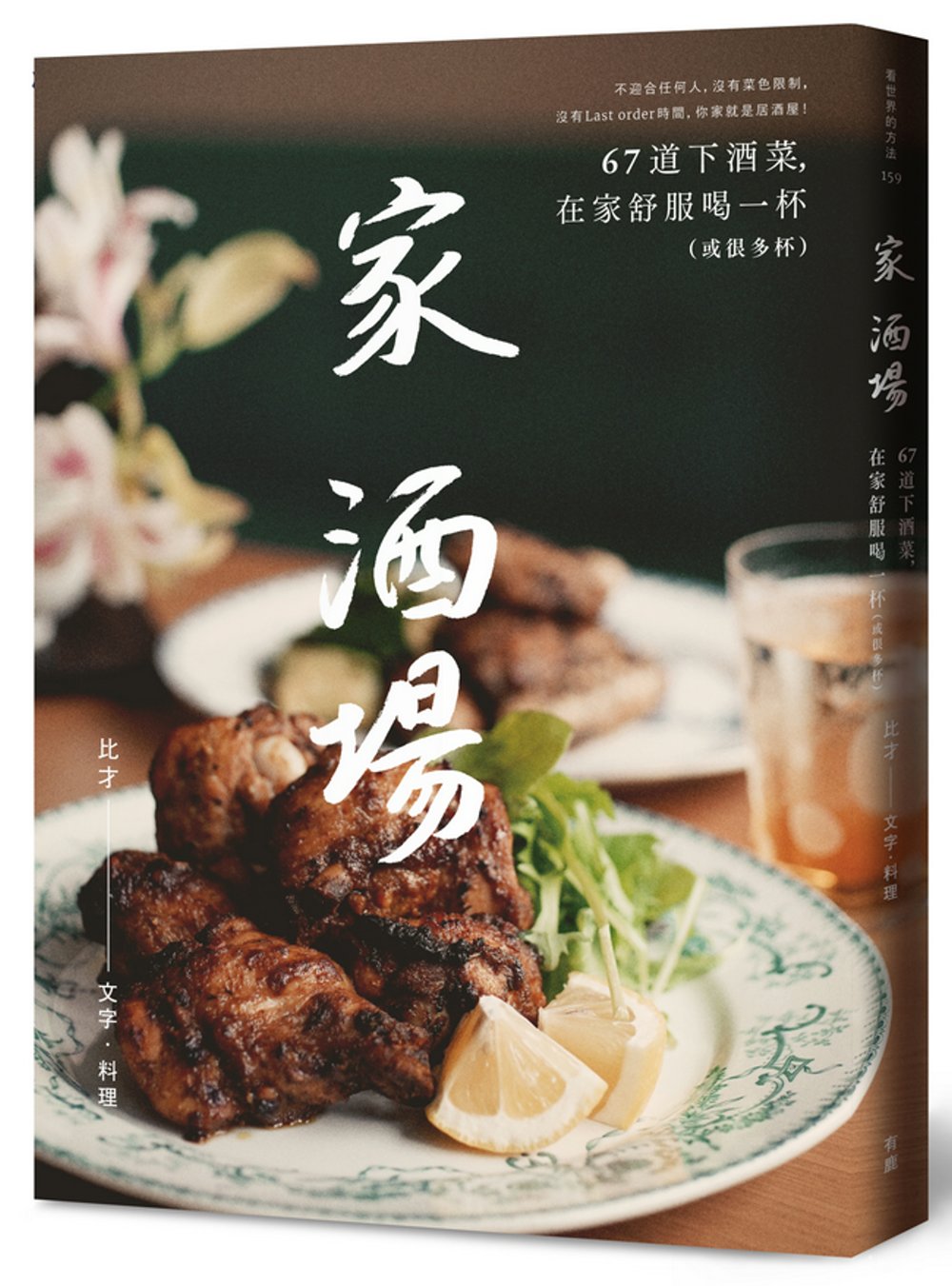

家.酒場:67道下酒菜,在家舒服喝...

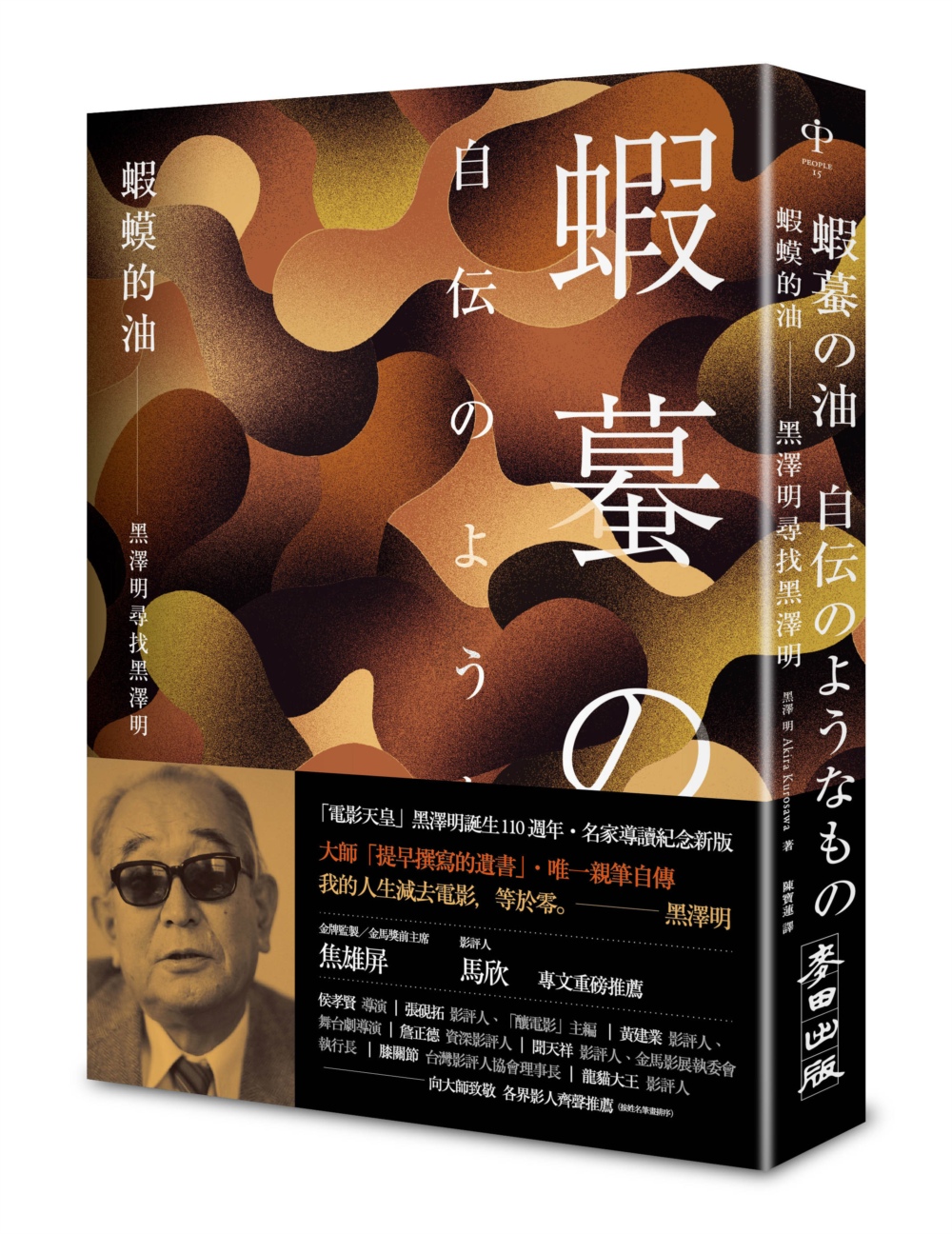

家.酒場:67道下酒菜,在家舒服喝... 蝦蟆的油:黑澤明尋找黑澤明(大師誕...

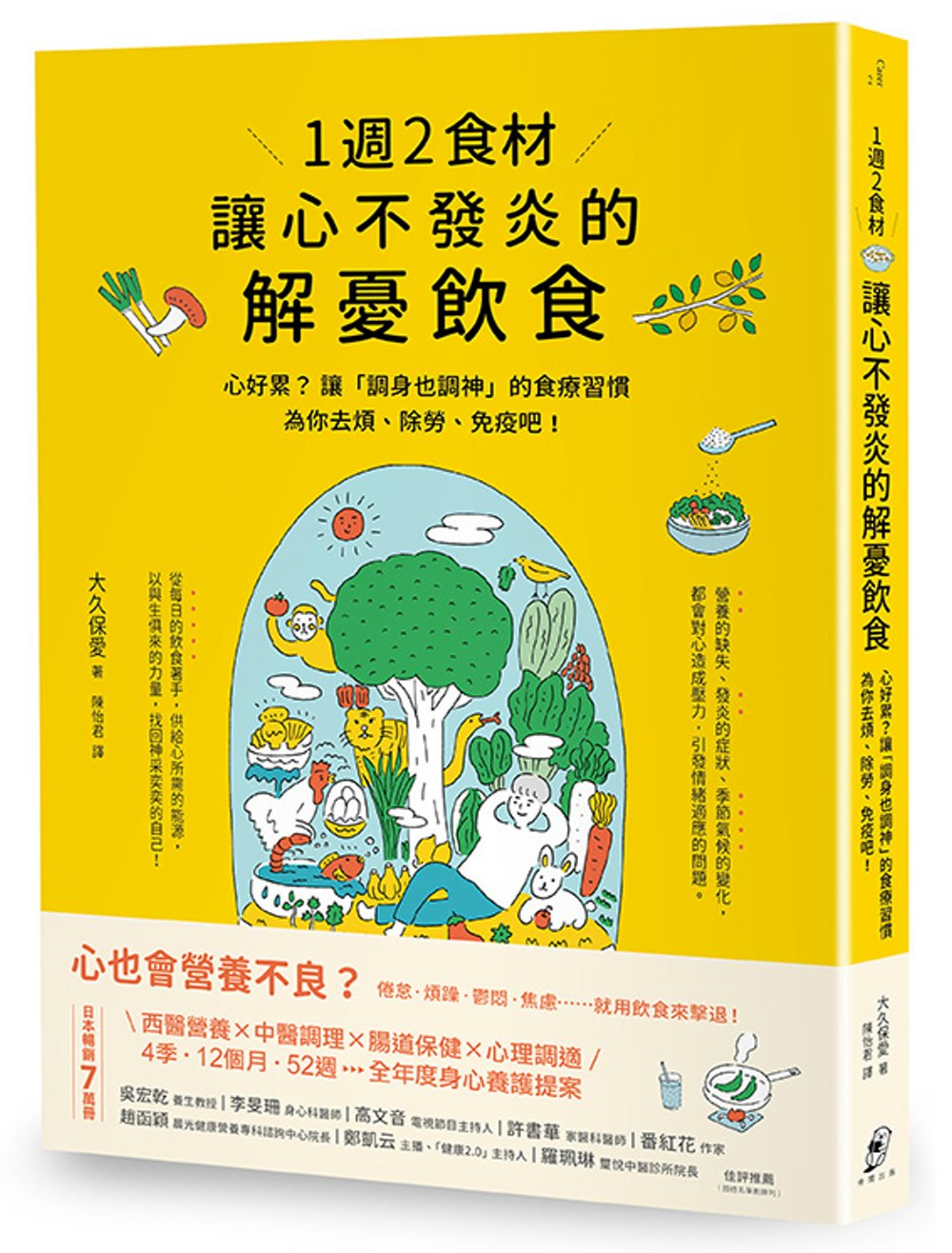

蝦蟆的油:黑澤明尋找黑澤明(大師誕... 1週2食材,讓心不發炎的解憂飲食:...

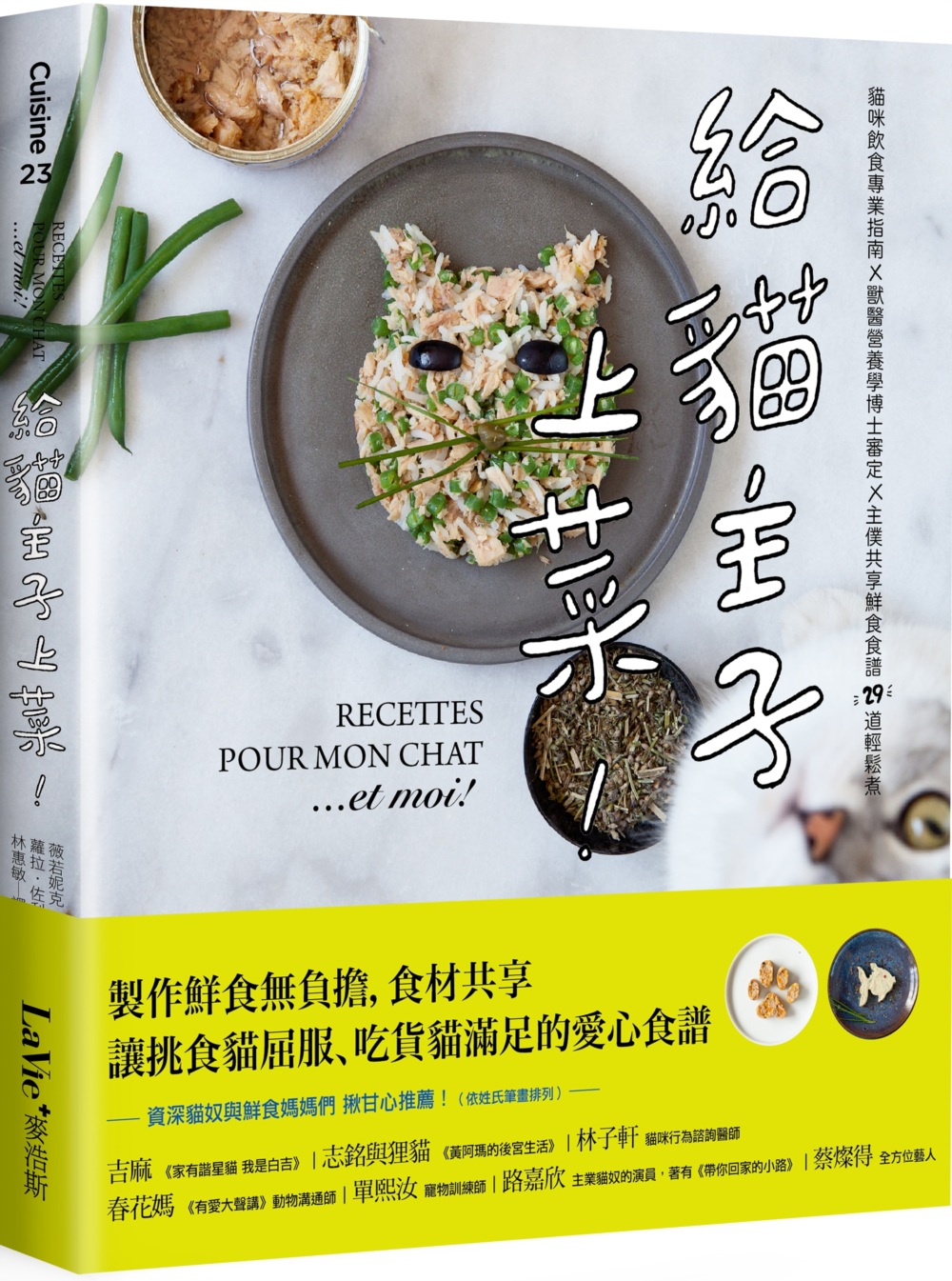

1週2食材,讓心不發炎的解憂飲食:... 給貓主子上菜:貓咪飲食專業指南x ...

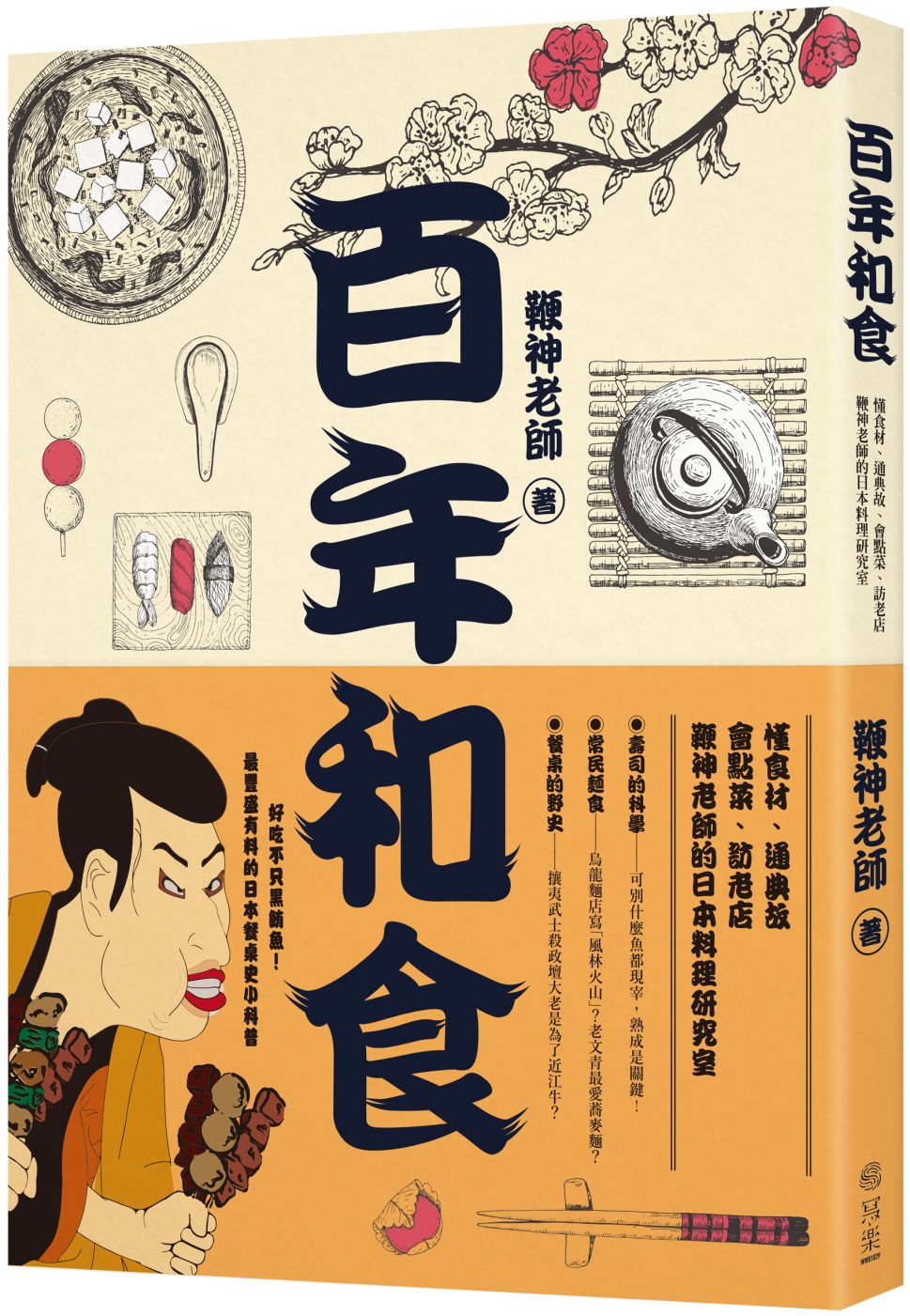

給貓主子上菜:貓咪飲食專業指南x ... 百年和食:懂食材、通典故、會點菜、...

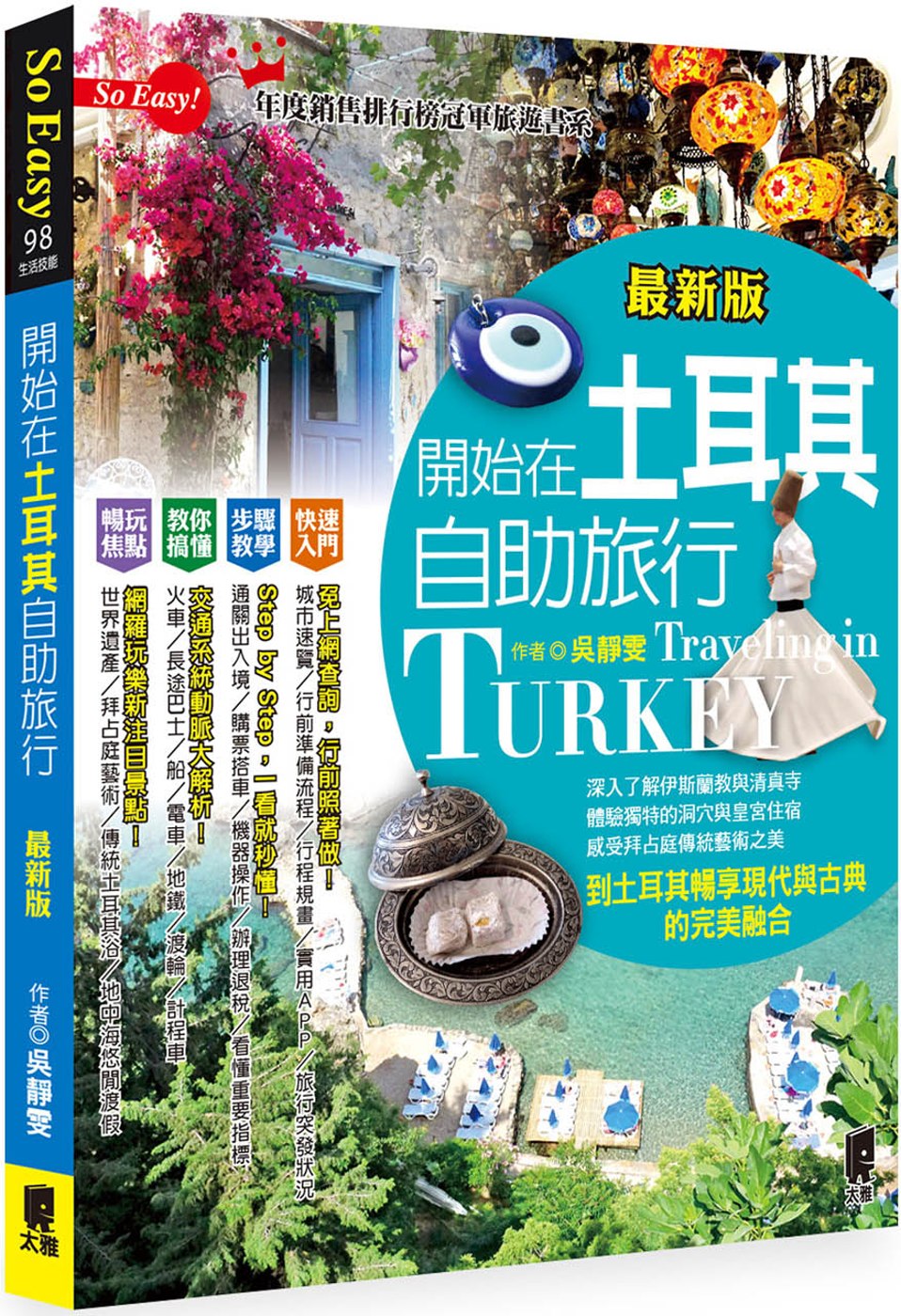

百年和食:懂食材、通典故、會點菜、... 開始在土耳其自助旅行(最新版)

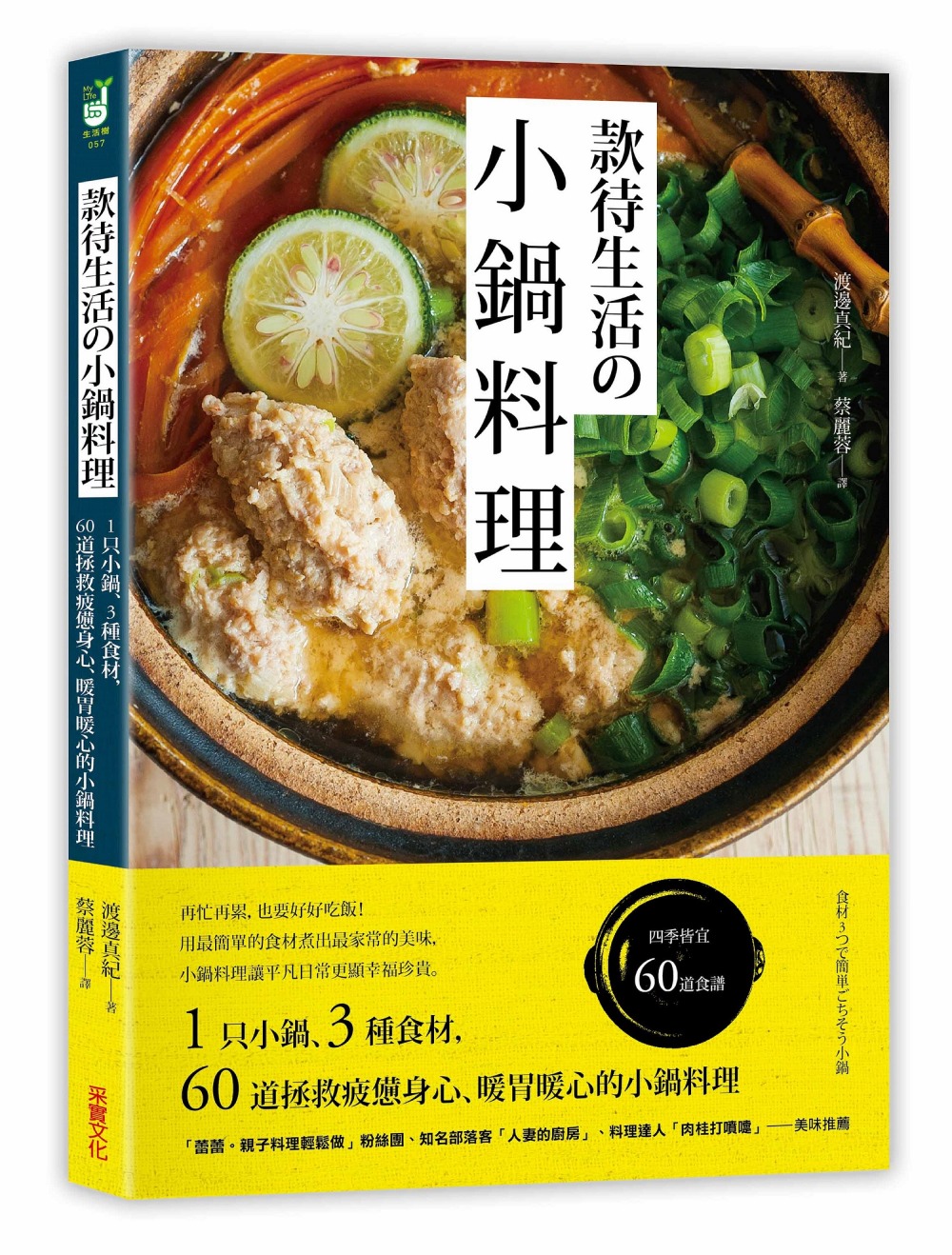

開始在土耳其自助旅行(最新版) 款待生活的小鍋料理:1只小鍋、3種...

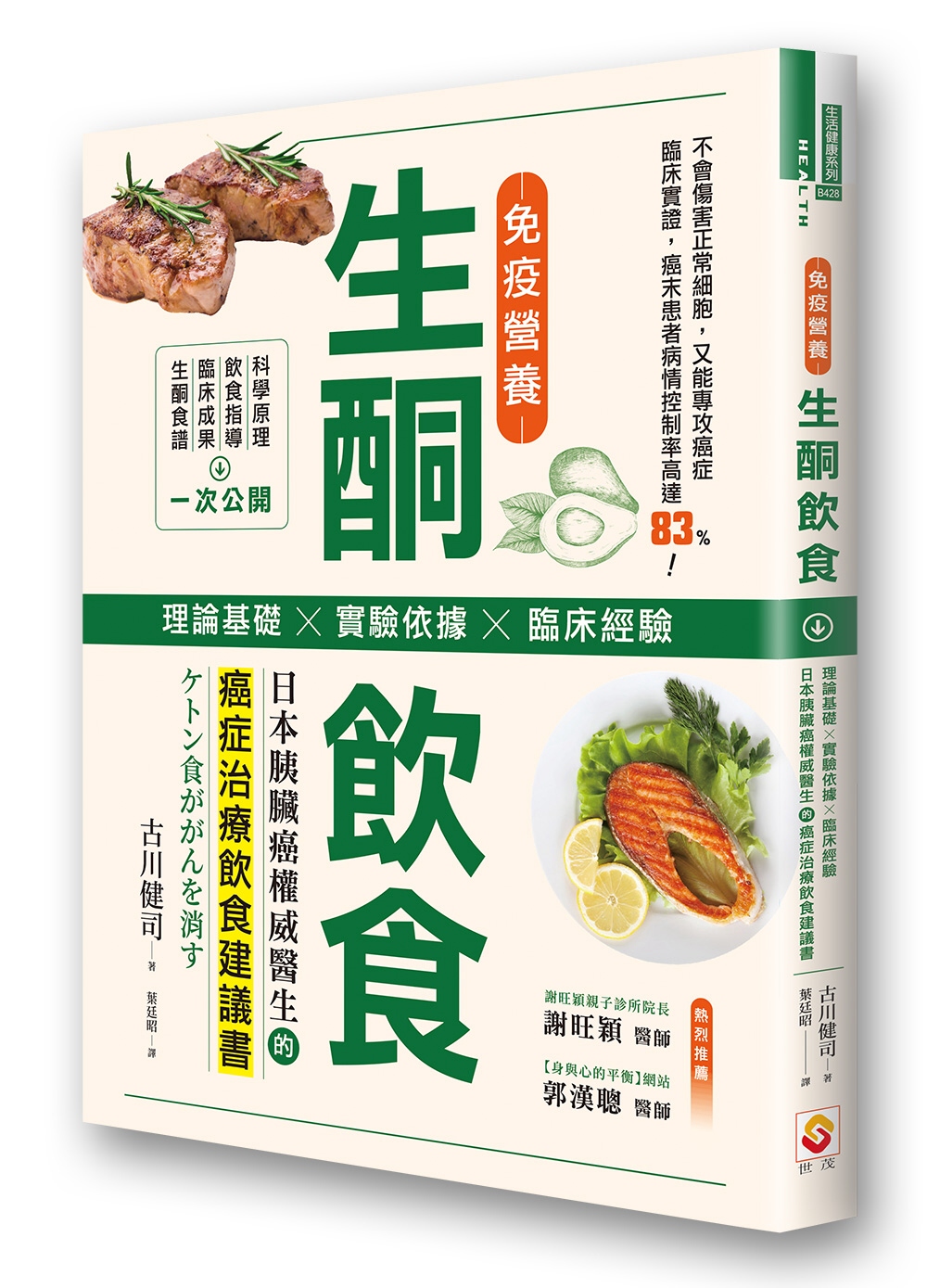

款待生活的小鍋料理:1只小鍋、3種... 免疫營養生酮飲食:理論基礎╳實驗依...

免疫營養生酮飲食:理論基礎╳實驗依... 海底躲貓貓:海洋生物總動員,怎麼找...

海底躲貓貓:海洋生物總動員,怎麼找... 日本權威營養師,萬人見證超簡易食療...

日本權威營養師,萬人見證超簡易食療...